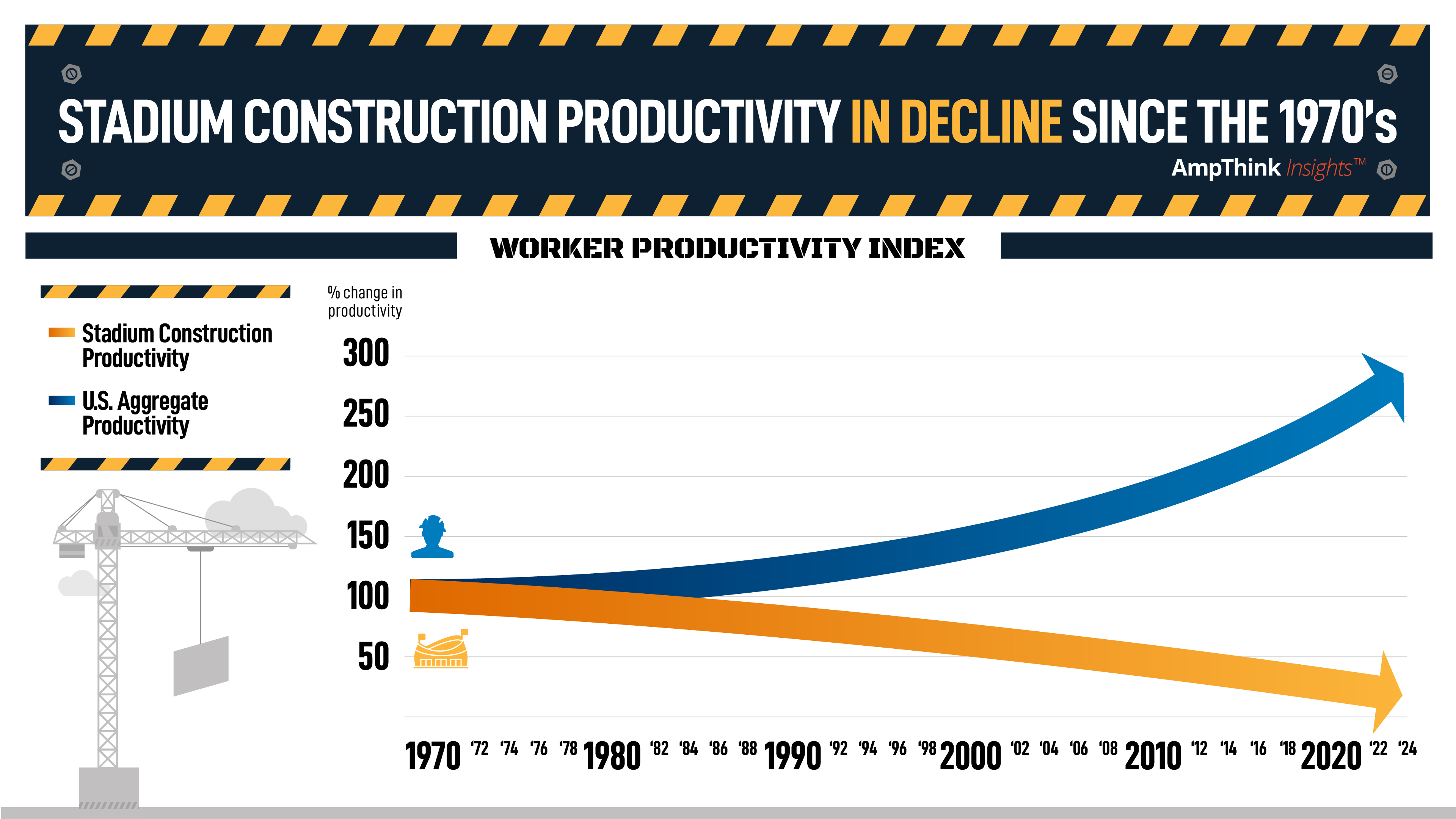

While nearly every American industry from manufacturing to agriculture has improved worker productivity since the 1960s, stadium construction has moved in the opposite direction.

Productivity in this context means output per hour worked: square feet built, or dollars of value delivered. In stadiums, that output per dollar spent is shrinking. Projects routinely run 30% over budget and miss their deadlines. And venue owners pay the price. This isn’t a new discovery nor is it unique to stadium construction. Experts have tracked construction’s productivity slump for decades. Headlines like “The Strange and Awful Path of U.S. Construction Productivity” and “McKinsey: Construction in a Productivity Rut” point to deep-rooted issues: fragmented scopes, inefficient coordination, outdated delivery models, and failure to adopt lean practices. And the problem is worse in stadiums.

Why? Because stadiums aren’t just buildings. They’re architecturally-unique, tech-heavy, custom-engineered environments requiring coordination across dozens of trades. Yet work scopes are often siloed, especially in technology. And tech is too often treated as a secondary concern. That’s a costly oversight. Technology has become a primary drier of stadium performance and now makes up 10–20% of total stadium construction budgets. In large venues, that translates to hundreds of millions of dollars. When the construction of technology systems is managed inefficiently, owners can easily overspend by tens of millions. There is a better way.

Even if the rest of a stadium project is delivered traditionally, tech can be delivered more efficiently. By unifying design, delivery, and integration under lean principles, owners can realize significant savings on one of the biggest and most complex parts of the build—and achieve better business results in the process.

At Ampthink, we use lean construction methods to cut waste while improving the performance of tech systems. From 10,000 seat soccer facilities to the largest football venues, we’ve consistently achieved savings up to 30% of technology costs across a wide range of stadium projects. The earlier we’re involved, and the more we are empowered to unify technology scopes under our lean model, the more control owners gain over cost, schedule, and outcomes.

Garland, TX 75042